More and more companies choose additive manufacturing as an option to manufacture components and for prototyping. This technology has enabled a large number of industries to improve their production output as 3d printing is a relatively quick way to produce parts. Nonetheless, after parts have been printed, most of these require to undergo a surface finishing process to get a nice smooth end product finish.

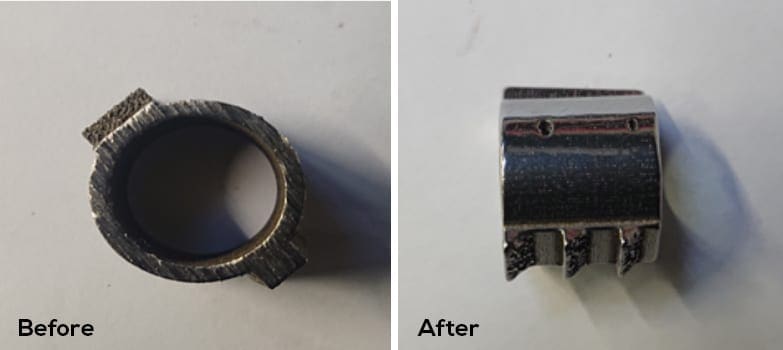

In this case study, we look at how you can achieve a smooth and polished surface finish on an Inconel 3d printed part in a short time.

Project Background

Client approached ActOn Finishing team to develop a process to allow him to achieve a smooth and polished finish on an Inconel 3d printed part. The part’s surface roughness average before being processed was 7.72 µm.

How we surfaced finished the Inconel 3D Printed Part

Due to the previous studies, we conducted on Inconel 3d printed parts, we decided that the most effective way was to finish the component was in the Centrifugal High Energy finishing machine. Some of the advantages of this machine includes:

- Shorter processing times, in comparison with traditional finishing methods;

- We built this technology particularly for applications like achieving a high surface finish requirement, a mirror finish and the removal of heavy manufacturing defects;

- The results are always consistent and repeatable

Further to our trials we achieved the final finish in a 2-stage process:

- To smooth the surface of the Inconel 3d printed part we used a mix of highly abrasive ceramic media, a concentrated cleaner and polisher compound and water.

- For the polished effect the component was finished in high density polishing media, using LQ9 compound, a specially formulated brightening and polishing compound. This compound is one of our best-selling products for polishing processes and is used by companies from a wide range of industries.

The result

This process achieved a 94% loss in roughness average, as requested by the customer (see table below for specific data). Furthermore, the smooth and polished finish required was achieved in only 5 and a half hours without affecting the part’s geometry.

| Part Identifier | Roughness Average Before Process (µm) | Roughness Average After Process (µm) | Total Ra Loss (µm) | %Ra Loss |

|---|---|---|---|---|

| Inconel 3D printed part | 7.72 | 0.84 | 6.88 | 94 |

If you would like to find out more information regarding our finishing expertise please check www.acton-finishing.co.uk, or contact our technical team at [email protected] . To check learn more about ActOn’s finishing technology for Additive Manufacturing industry please visit the Industries page.