At ActOn Finishing we offer shot blasting systems, including portable abrasive blast machines, suction blast, pressure blast and wet blast cabinets and a range of automated systems. These machines are designed to guarantee reliable operation and a long service life. ActOn shot blasting cabinets offer the possibility to achieve a wide range of finishing applications.

ActOn Shot Blasting Systems

The ActOn offering includes a range of portable, economical, premium and automated shot blasting systems. These blast cabinets are designed for blasters who require rapid, repeatable and efficient blasting results, a process free of interruption and a shot blasting machine with a solid construction. More over all components are assembled, according to ISO-certification, to create a compact turn-key unit.

The new range of shot blasting equipment will include the ECO Shot Blasting Machines, Premium Blasting Cabinets, Portable Series & Automated Shot Blasting equipment and a special range for the additive manufacturing market.

The new range of shot blasting equipment will include the ECO Shot Blasting Machines, Premium Blasting Cabinets, Portable Series & Automated Shot Blasting equipment and a special range for the additive manufacturing market.

The ECO Series

The ECO Blasting Series includes an economical range of Suction Blast and Pressure Blast machines. These machines have been designed to allow you to minimise your investment while enjoying the benefits of a good quality shot blasting machine. Both the ECO MI Series (Suction Blast) and the ECO MP Series (Pressure Blast) are built to achieve a rapid and efficient finish.

The Premium Series

The Premium Blasting Series includes a range of DI Suction Blast, NP Wet Blast and DP Pressure Blast machines. These machines have been designed for blasters with high requirements when it comes to blasting results, user convenience, safety and environment.

The DI Suction Blasting cabinets are equipped with a cyclone, which guarantees that the abrasive is cleaned perfectly. This results into less wear and better visibility. The suction blast pistol ensures, in combination with the mixing chamber, a constant optimum mix of pressurised air and abrasive, to offer an effective and efficient blasting process.

The NP Wet Blasting cabinets are equipped with a special pump that achieves a constant flow of blast media and water to the blast nozzle.

The media and water is mixed with pressurised air to add extra power and speed to the mix. The result is a very smooth finished component. The water and abrasive are collected in a funnel, and the pump provides an agitation so that the abrasive continues to “float”. NP Wet Blasting cabinets are perfect for applications such as cleaning, descaling, deburring, roughening, oil or grease removal, die cleaning as dimensions are not affected, or to achieve a smoother surface.

The DP Pressure Blasting cabinets are equipped with a cyclone, which guarantees that the abrasive is cleaned perfectly. This results in less wear and better visibility. The pressure pot is equipped with a dosage cylinder which always ensures the right mix of abrasive and pressurised air. Also, the dosage cylinder controls a constant flow of an abrasive, even at the start of the blast process. This results in an effective and efficient blast process.

Portable Abrasive Blast Systems

These machines are our smallest industrial blast machines which offer the perfect balance between productivity & portability. The Portable Abrasive Blast Systems are user friendly, an economical shot blasting machine option & perfect for surface preparation.

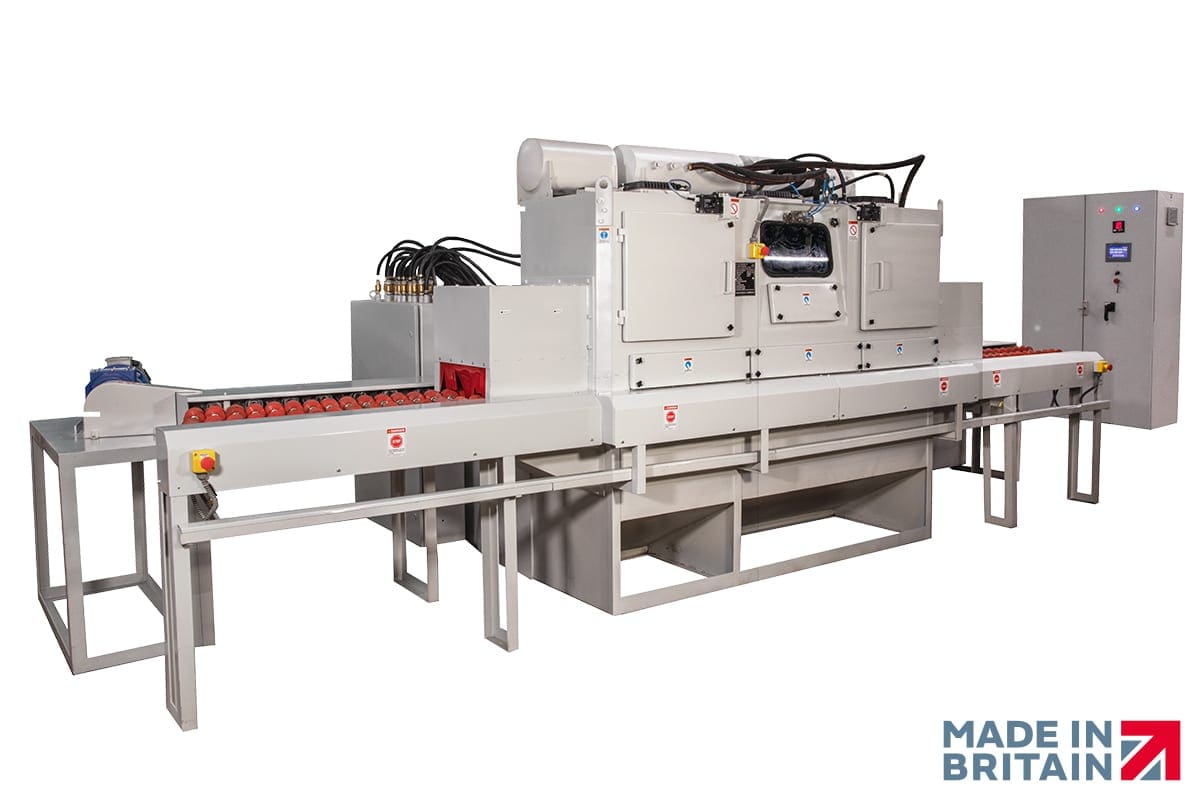

The Automated Shot Blasting Systems

The main advantages of the ActOn automated blasting systems are the reduced manual handling and consistent high-quality finishing results. The automated systems are operator friendly, and can be custom built to suit your needs. We will offer you full support every step of the way.

This range includes: Satellite Blasting Cabinets, Drum Blasting Cabinets, Transit Blasting Cabinets, Turntable Blasting Cabinets, Shot Peen Blast Installations, Internal Blasting Cabinets and Rollers and Tubes Blasting Cabinets.

Sid Gulati, Managing Director at ActOn Finishing, said the ActOn Blasting Cabinets fit perfectly with the firm’s existing range of mass finishing products. He states: “We are continuously developing and adding new products to our range of finishing solutions and are certainly excited with our new range of shot blast technology. ActOn are here to offer you a complete solution."

To find out more about our shot blasting technology available from ActOn Finishing, download our brochure or you can also call us at +44 (0) 24 7646 6914 or send us an email at [email protected]⠀⠀⠀⠀⠀